CAD/CAM Technology – ZirkonZahn

In recent years, the digitization and computerization of most services has been constant and transversal to all areas. Dentistry has undergone major innovations in our daily clinical practice.

From the scheduling and confirmation of a patient’s appointment through automated services, to the taking of impressions through intra-oral scanners, to the detriment of impressions with materials (namely silicones and alginate) that cause simple reflux; the manufacture of the dental prosthesis, until it is delivered to the patient by the dentist.

It was with the improvement and speed of execution of dental prostheses in mind that CAD/CAM systems in Dentistry appeared.

CAD/CAM is the English abbreviation for Computer Aided Design / Computer Aided Manufacture, in Portuguese, Computer-aided design / Computer-aided manufacturing.

The appearance of this type of technology dates back to the early 50s, where the first lines of programming began to be thought of and developed. Nowadays, it is a technology very present in large technological areas, as well as in the aeronautical industry and in the automotive industry, for the execution of automotive parts, for example.

In Dentistry, the emergence of CAD/CAM systems has strongly revolutionized the areas of Oral Rehabilitation, and more recently, in Oral Implantology.

According to the website of the Portuguese Dental Association (OMD), CAD/CAM in dentistry “is about computer-aided processes for the design and manufacture of custom-made dental devices or customised dental devices from an industrial product” sic.

The integration of these technological systems together with the evolution of dental biomaterials, such as zirconia, which is a high-strength ceramic, has led to major changes in education and patient care.

Consequently, the entire panorama of education in Dentistry has been and will continue to be changed in economic terms, in time effectiveness and, most importantly, in postoperative forecasting, in dental treatment specifically, as well as in the delivery of fixed prosthesis treatment.

In this way, the patient’s Oral and Aesthetic Rehabilitation has become an integral and complex sequence of techniques that involve the patient, the dentist and the dental technician. One of the advantages of this system is the predictability it gives to all types of work it performs, since, even before performing procedures in the oral cavity, it is possible to predict what the final result will be.

Not only is it very stimulating and motivating for the patient himself, but it is also easier to achieve excellence and greater patient satisfaction. The patient thus becomes an active part of his or her own treatment.

In our CERO laboratory, we have this type of CAD/CAM technology available to the clinic and our patients, which is supported by the German representative and reference ZirkonZahn.

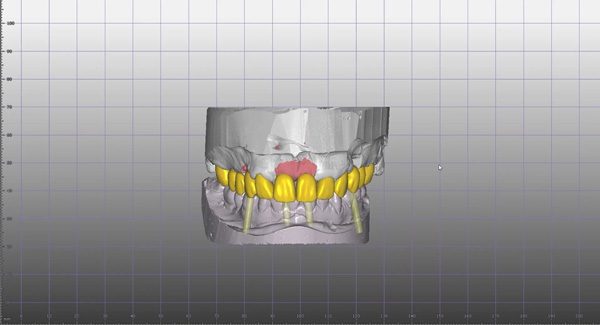

In practice, this technology is divided into two phases. In the first, the CAD (computer-aided design) phase, a scanner or digitization of the teeth is carried out, which can be directly in the mouth or through a plaster model, which will create “digital information” that can be changed through a computer. This “digital information” through its own programs (ZirkonZahn software) will create a virtual model that It will simulate the patient’s mouth on a computer.

In this way, all types of desired changes can be made, such as the placement of missing tooth pieces, replacement of fractured or worn ones, as well as aesthetic modifications by increasing and changing the shape of the teeth.

In the second phase of CAM (computer-aided manufacturing), virtually created dental parts will be milled and transformed into physical dental parts. This transformation is carried out through our own milling machines, in our case we use the milling machine of the same commercial brand (ZirkonZahn). This milling machine will perform high precision cuts in blocks of chosen material (Zirconia, Lithium Disilicate, Metal, PMMA, etc.), originating and shaping the prosthetic parts initially designed.

This technology has revolutionized the Dentistry sector, providing greater speed in the delivery of work, greater safety and predictability of the final result.

In an era where there is more and more talk of reducing, reusing and recycling, this technology has allowed the use of a smaller amount of materials used in both printing and molding as well as the inherent replacement of transport through couriers by electronic transmission, resulting in obvious advantages for the environment.

The CERO clinic is committed to providing its patients with the best possible experience throughout their treatment.